Our Services and Products

- ISO9001:2015 Registered

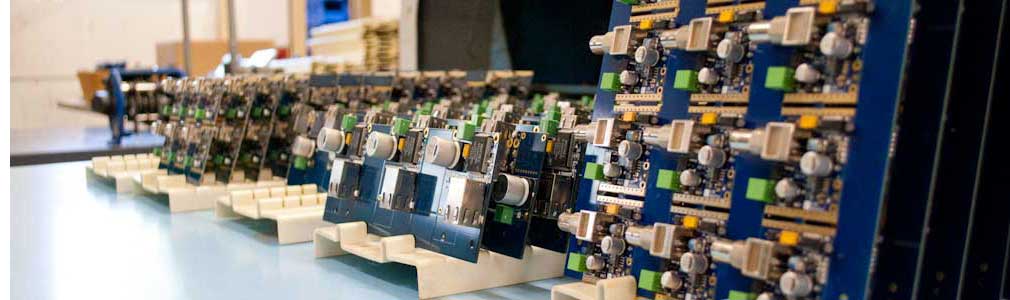

- Printed Circuit Assembly

- Surface Mount Technology

- Through-Hole Technology

- Mixed Technologies

- Prototypes

- Automated Processes

- Component Prep

- Wave Soldering

- Computer Inventory

- Sequencing

- Chassis/Panel Wiring

- Consignment/Turnkey

- ESD Protection per s20.20

- IPC-610B

- Lead Free/RoHS or Lead Solder available

- Assembly process of surface mount from blank Printed Circuit Board to final assembly.

- Placement of parts as small as 0402 sized. No maximum.

- Assembly of mixed surface mount and through-hole PCBs.

- Assembly of solely through-hole assemblies.

- Machine insertion and Hand insertion.

- Automatic inspection.

- Functional testing capabilities.

- Final box build assembly.

- Prefer customer to supply parts, but may also do turnkey depending on the volume and cost.

(Customer supply of parts allows for lower cost.)

Equipment:

Surface Mount

- Samsung SM482, line 1 pick and place

- Samsung SM482, line 2 pick and place

- Samsung IT Inventory Control

- DEK Horizon Stencil Printer

- Contact Systems 3S, low volume prototype

- OK Industries SMT-6000, manual pick and place

- Heller reflow ovens (3)

- Metcal BGA & CSP Rework System

- MPM Speedline automatic printer

- Opti-Print 2020 semi-automatic printer

- Opti-Print 1616 manual printer

- APS Gold manual printer

All printers are compatible with QTS (Quick Tension System) framed stencils.

Stencil printers range from manual to automatic depending on complexity of the product.

Inspection

- Mirtec MV-3L automatic inspection

- SMG Enterprises Video microscope

Through-hole assembly

- Universal Sequencer

- Universal VCD automatic Through-hole insertion

- Universal DIP automatic IC insertion

Additional

- Aequeous Systems Deionized PCB washer

- FKN Systek Depanelizer

- Climate controlled Board Storage Room

- Zebra 90XiII Label Printer

- Wire cutting and stripping equipment

- Trieber Leaded wave solder machine

- NovaStar Lead-free wave solder machine